Industrial Solutions for High Precision Cutting

As Mikro Makina, the industrial cutting blades we have developed for the rubber and plastics industries are designed to provide high precision, durability and long-lasting performance. Our products are tailor-made to offer maximum efficiency on both manual and automatic cutting lines.

Production Technology and Material Selection

Our rubber and plastic cutting blades are machined with micron tolerances on our 4- and 5-axis CNC machines. The materials we use in the blades are diversified as follows according to the type of application:

HSS (High Speed Steel): Ideal for thermoplastics and softer rubber types. The cutting edge remains sharp for a long time.

Tungsten Carbide (Carbide Tipped or Full Carbide): Preferred for intensive production lines due to its high wear resistance. Especially recommended for cutting hard PVC, PE and similar engineering plastics.

Stainless Steel (DIN 1.4034 / 1.4112 etc.): Preferred in applications where chemical resistance is important. Suitable for operation in sterile or humid environments.

Design Features

The blades we design for each application are available in the following technical variations:

Straight Cutting Blades: Optimized for linear cutting in automated lines.

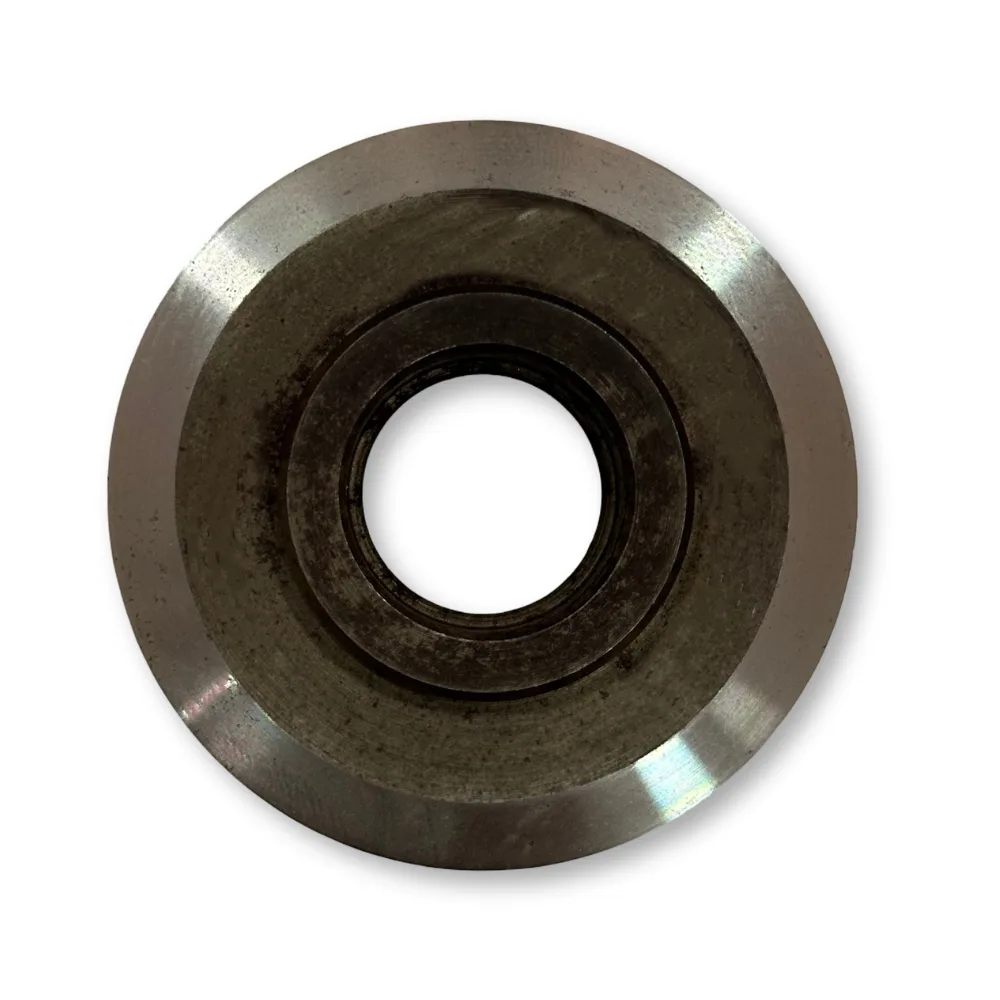

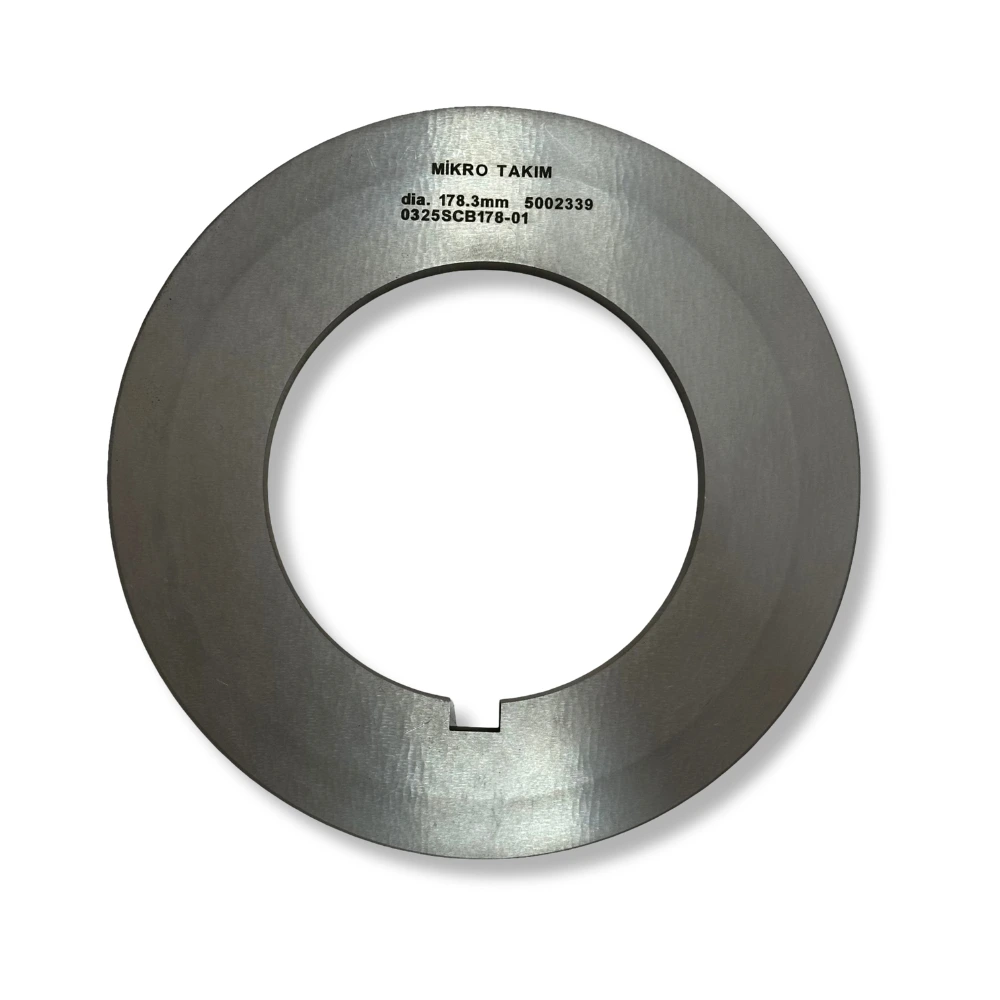

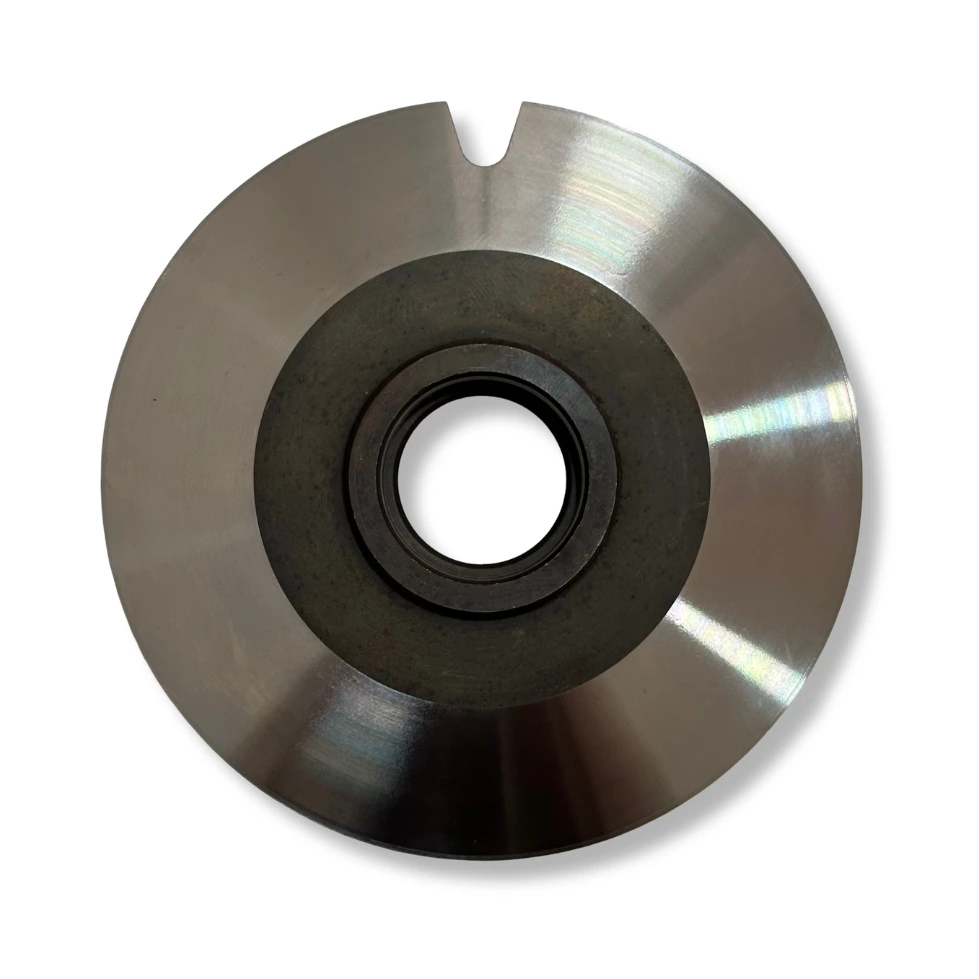

Circular Cutting Blades: Used in rotary systems, these blades create minimal burrs and deformation during cutting.

Serrated and Micro-Tooth Blades: Improves cutting precision by providing more grip on slippery or flexible materials.

Angled and Profile Cutting Blades: Used for cutting specially shaped plastic profiles. Minimizes shape distortion after cutting.

Surface Treatment and Coatings

Various surface coatings and treatments are applied to improve cutting performance and blade life:

TiN (Titanium Nitride) Coating: Reduces friction and increases surface hardness.

TiAlN / DLC Coatings: Ideal especially in applications where cutting is performed under high temperature.

Cryogenic Heat Treatment: It provides a more homogeneous and long-lasting cutting structure by improving the microstructure of the steel.

Areas of Use

Our rubber and plastic cutting blades are widely used in the following industries

- Automotive parts production (wick, gasket, cable duct cutting)

- Rubber and plastic cutting

- Packaging and plastic bag production

- Footwear and sole production

- Artificial leather and upholstery industry

- Production of industrial gaskets and sealing elements

Customized Production and Technical Support

Special sizes, forms and tolerances are produced according to customer demands. Our technical team provides support at every stage, from choosing the right blade to process optimization. Our quality control processes ensure high performance and consistency in both initial sample production and mass production requests. Contact us now for customized solutions for your needs!